Machine Tools

Always moving forward for you

When our products are used in the machine-tool field, everything revolves around the highest switch-on times with the highest rotational speeds. And for these special requirements we have very special solutions.

When our products are used in the machine-tool field, everything revolves around the highest switch-on times with the highest rotational speeds. And for these special requirements we have very special solutions.Precise, high-torque and fast – the feed drives in the machine tools are designed, among other things, with our straight bevel gear pairs – also as a master-slave combination that includes a toothed rack. This guarantees high levels of stiffness and dynamics.

The auxiliary drives of the machine tools are as varied as they are demanding: during processes such as sawing, drilling, milling, planing, pressing, grinding, machining and finishing – to mention just a few – clamping, rotating and centring must be efficient. Our experienced engineers find an optimum solution here. This is also confirmed by a large number of references from well-known customers. Incidentally: our engineers are also happy to work together with customers or according to a requirements specification sheet to develop special solutions for machine-tool construction. Because we love a challenge

Image source: CHIRON Werke GmbH & Co. KG

Robotics und Automation

Man and Machine Hand in Hand.

We are the robots – this title granting a hit for the German band Kraftwerk in the 1970s applies more than ever today. Robots are becoming more and more indispensable from an economic perspective for an increasing number of tasks in a wide range of industries. For the perfect interplay between man and machine, for the perfect accomplishment of specific tasks.

We are the robots – this title granting a hit for the German band Kraftwerk in the 1970s applies more than ever today. Robots are becoming more and more indispensable from an economic perspective for an increasing number of tasks in a wide range of industries. For the perfect interplay between man and machine, for the perfect accomplishment of specific tasks. As we are a competent partner for demanding customers, you can count on our long-standing experience in robotics and automation. During the development of the powertrain, particular attention is paid to availability and resilience. High-precision toothing solutions inside the gearbox as well as all-round system solutions are our speciality.

Furthermore, we offer an all-round standard range of dynamic angular gearboxes which stand out due to the fact that with minimal adjustments they are perfectly suited for a broad range of automation solutions. All of our products feature the highest levels availability and system stability, coupled with power density and optimum energy efficiency.

Image source: Kuka Roboter GmbH

Drive Technology

Our drive: your success

Your competitiveness drives us forward. Specifically, this means: we develop highly efficient bevel gear units as a preliminary stage or post-stage in conjunction with connected planetary gear units or other precision gears. With the highest precision, small installation space and the highest torques

And our customers can rely on over 60 years of experience and our pronounced enthusiasm for innovation in the field of drive technology. This is demonstrated every day by Graessner gearboxes in virtually all industrial sectors.

Not least the extremely high levels of reliability and durability of our drive solutions enable our end customers to carry out reliable and plannable production. Our products and services therefore reliably safeguard the production of the industrial plants of our customers and their customers all over the world.

Our range of services is almost unlimited: we offer the entire engineering of the powertrain and its production, including service. This includes, among other things, toothing solutions, angular gearboxes, spur gear units and planetary gearboxes for a wide range of applications. When developing customised solutions we think outside the box – by means of a holistic approach to the tasks we are set.

Image source: TAKRAF GmbH

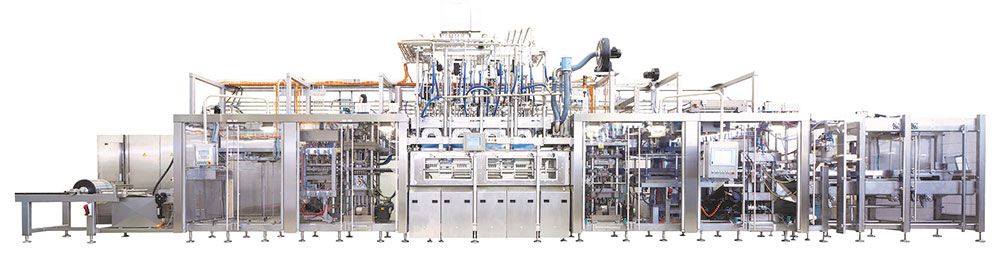

Packaging Machines for the Food Industry

Bon appetit! – Our gear units are pure pleasure.

Hardly anywhere else are the demands placed on cleanliness greater than in the food industry. Also on the availability of the filling and packaging machines – because a standstill can be expensive.

The stainless steel or coated designs of our gearboxes fulfil these high hygiene requirements. They allow optimum cleaning with the minimal adhesion of dirt. Food-safe lubricating oils are used as a matter of course. And what drives us on: developing particularly energy-efficient drives and generating solutions which make it possible for machine manufacturers to create genuine competitive advantages for their customers from the food industry.

Image source: ILLIG Maschinenbau GmbH & Co. KG

Measurement and Testing Technology

Trust is good, control is better!

The corporate landscape nowadays is shaped by faster and faster time-to-market processes. Due to the ever shorter cycle times for new products, highly efficient test beds are particularly important. We have experience with these – because for decades we have been providing support to our customers with special test bed gearboxes.Our highly dynamic labyrinth gearboxes satisfy all requirements with respect to efficiency and running smoothness.

For example, we offer the automotive industry, with its modern production processes and high level of automation, efficient solutions for their test beds.

Image source: AVL Schrick

Medical Technology

The technology behind modern medical technology

State-of-the-art drive technology and innovative medical technology solutions often go hand-in-hand nowadays. Our mechanical drive solutions are therefore used in many areas of medical technology.

State-of-the-art drive technology and innovative medical technology solutions often go hand-in-hand nowadays. Our mechanical drive solutions are therefore used in many areas of medical technology.Small angular gears, for example miniature gearboxes made of stainless steel with planetary gear as the preliminary stage, are frequently used for therapeutic devices, among other things. Here, it is possible to offer the patient long-term assistance with efficient accumulators and our drive solution. For example in intelligent prostheses and many other solutions in the eHealth field. Not for nothing are our customers in this field mostly high-tech companies and innovation leaders.

Technical expertise in conjunction with a high level of safety for our systems are of the highest priority. Additional assistance during the development and subsequent pilot run production is guaranteed by our numerous calculation and design programs. Our equally well-founded and broad knowledge of the field of medical technology forms the basis for our ability to find solutions quickly. It is therefore no surprise that our medical technology solutions both at home and abroad are highly appreciated by customers and patients alike.

Image source: ReWalk Robotics, Ltd.

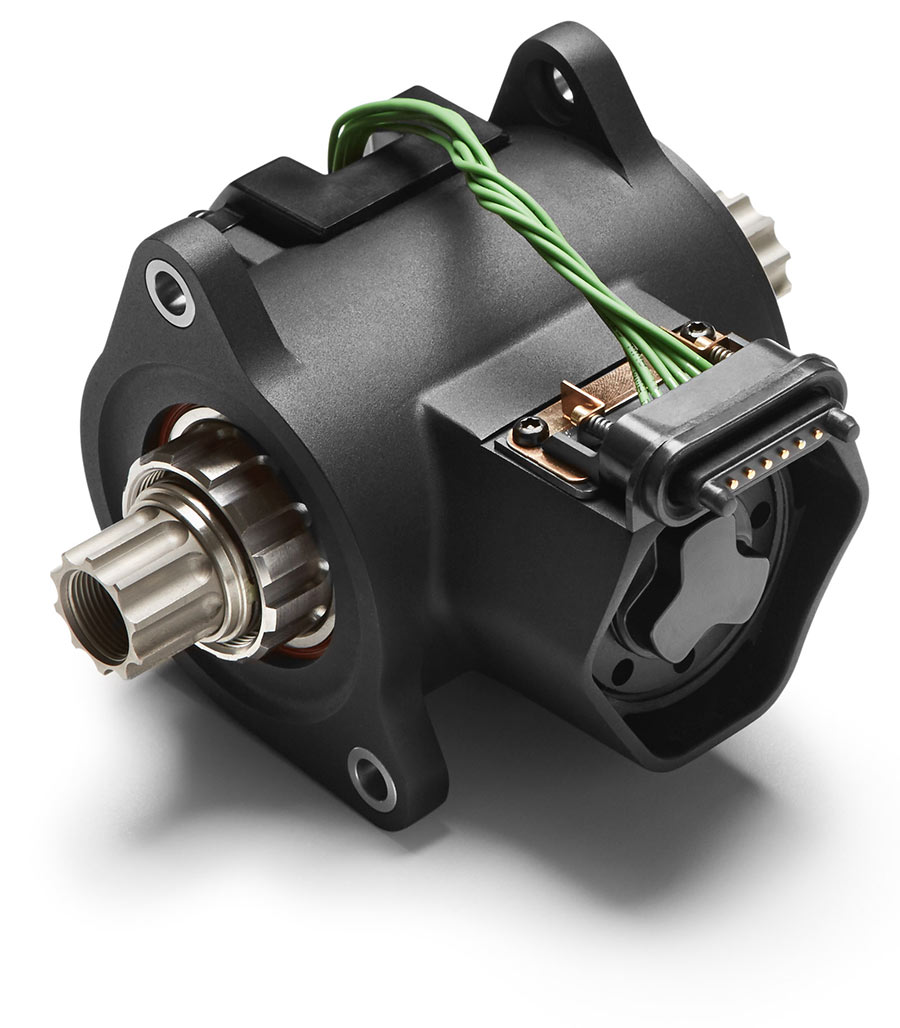

E-Motive

The whole world in motion

E-motive moves the world. In this field we also have our noses in front – our long-standing experience of electric mobility sets international standards. For some years now we have been a competent development partner for our customers in the e-motive field. We are the point of contact for the development of e-bikes, lawnmowers, pleasure craft or parking aids – to name just a few products. Our expertise across the entire powertrain enables us to produce energy-efficient systems with a high service life.

E-motive moves the world. In this field we also have our noses in front – our long-standing experience of electric mobility sets international standards. For some years now we have been a competent development partner for our customers in the e-motive field. We are the point of contact for the development of e-bikes, lawnmowers, pleasure craft or parking aids – to name just a few products. Our expertise across the entire powertrain enables us to produce energy-efficient systems with a high service life.Our drive solutions impress with their high power density, low weight and outstanding level of efficiency.

Our range of services: we offer the entire range of technical design for the e-motive field – also for hybrid and electric vehicles. Our offers are rounded off by our in-house service package with experienced engineers.

Mechanical and Plant Engineering

Our guiding principle is nothing less than to set standards

For over 60 years we have been the competent partner for companies from the field of mechanical and plant engineering. Strictly speaking, our guiding principle is always the same: a size which is as compact as possible with the simultaneous transmission of high torques. And we translate this principle into practice individually with each project – always with the objective of setting standards.

For over 60 years we have been the competent partner for companies from the field of mechanical and plant engineering. Strictly speaking, our guiding principle is always the same: a size which is as compact as possible with the simultaneous transmission of high torques. And we translate this principle into practice individually with each project – always with the objective of setting standards.Whether angular gearboxes or other mechanical gear units are involved, our guiding principle is always to be the number 1 technically. We also manufacture high-precision spur and bevel gear sets, planetary gear units as well as dynamic and robust bevel gear units for a wide range of applications.

In the development of customised solutions in particular we are unique in terms of our in-house processes such as our efficient workflow management. And we are delighted that our many customers see things the same way – and confirm this to us through long-standing customer relationships.

Image source Quelle: Cantec GmbH & Co. KG

You have any questions?

We will be glad to help you.

Germany

Nidec Graessner GmbH & Co. KGTHE GEAR COMPANY

Kuchenaecker 11

72135 Dettenhausen

Germany

+49 7157 123 0

+49 7157 123 212

mail@graessner.de

www.graessner.de