Nidec Graessner – Engineering

For everyone who expects more: special gearboxes from the specialist.

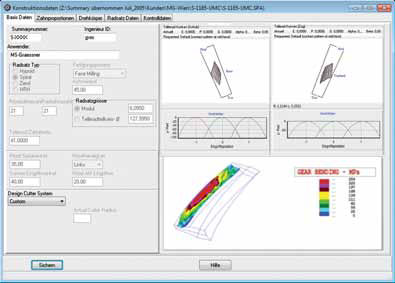

Our engineering and special manufacturing techniques have helped us become precision manufacturer of tooth systems and bevel gearboxes for more than 60 years, as well as specialist in special gearboxes.For us, individual solutions are standard. And instead of offering expertise that‘s confined to certain areas, like pure development for instance, we offer comprehensive know-how in all relevant areas – from the specifications and the first sketch up to the manufacturing of the zero series including intensive test operations.

Our expertise also extends to a special in-house developed workflow management system: for optimal processes between all areas involved and the customer. Our quality management system thus guarantees highest quality and cost certainty.