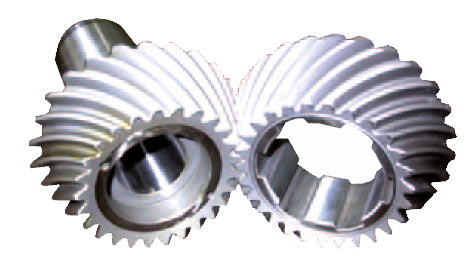

BevelGear – Customised Bevel Gears

Almost no-one understands complex construction as well as Nidec Graessner, due to the fact that the gear tooth and gear specialist‘s creations are based on more than 65 years of experience. Intelligent solutions for a wide range of sectors and applications make Nidec Graessner a reliable industry partner in both gear tooth technology and gear construction.| Module ms min. |

Module ms max. |

max. outer edge of gear Ø (A) |

max. tooth width (B) |

max. outer bevel distance |

Shaft angle (B) from |

|

| Spiral bevel gears |

0,5 | 12,0 | 410 mm | 66 | 280 | 10° to 170° |

| Hypoid bevel gears |

0,5 | 12,0 | 410 mm | 66 | 280 | – |

| Zerol® bevel gears |

0,5 | 12,0 | 410 mm | 66 | 280 | 10° to 170° |

(B) dependent on outer bevel distance

| Module ms min. |

Module ms max. |

max. outer edge of gear Ø (A) |

max. tooth width (B) |

max. outer bevel distance |

Shaft angle (B) from |

|

| Spiral- Kegelräder |

0,8 | 10,0 | 280 mm | 66 | 280 | 10° to 170° |

| Hypoid- Kegelräder |

0,8 | 10,0 | 280 mm | 66 | 280 | – |

| Zerol®- Kegelräder |

0,8 | 10,0 | 280 mm | 66 | 280 | 10° bis 170° |

(B) dependent on outer bevel distance