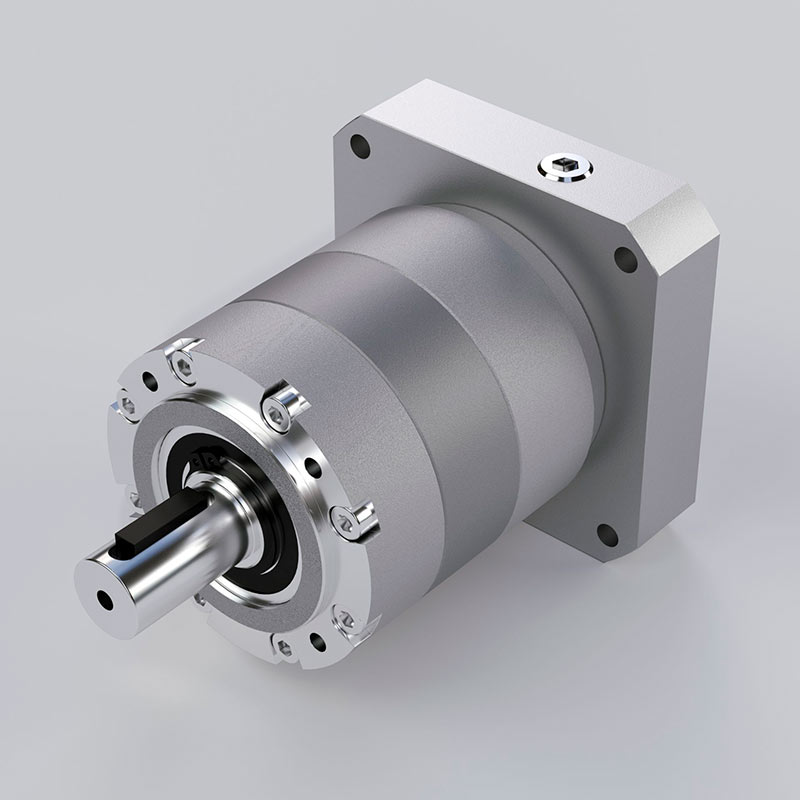

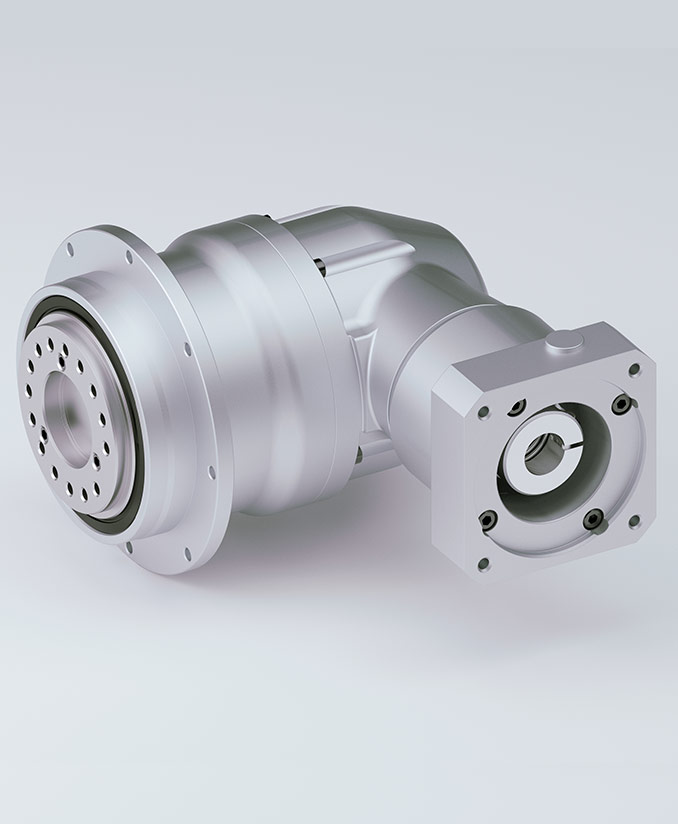

11/2022 PLANETGEAR VRS High Speed: Cool – even at high speed operations

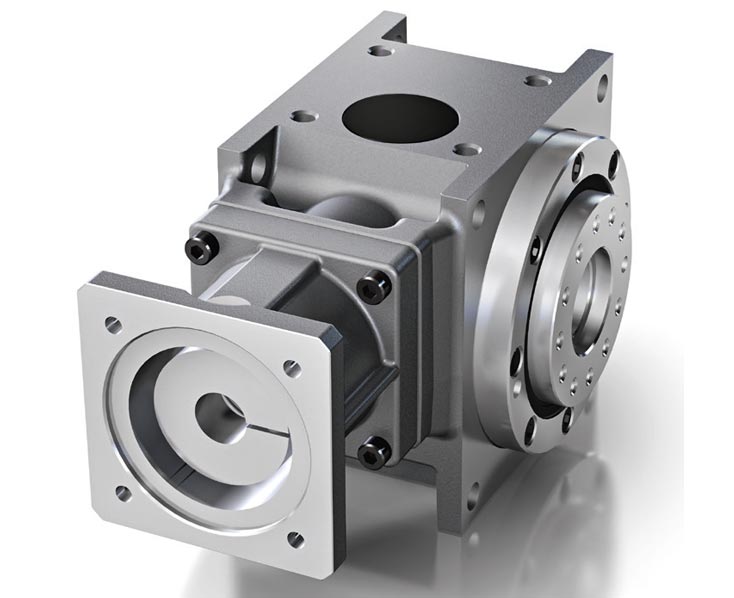

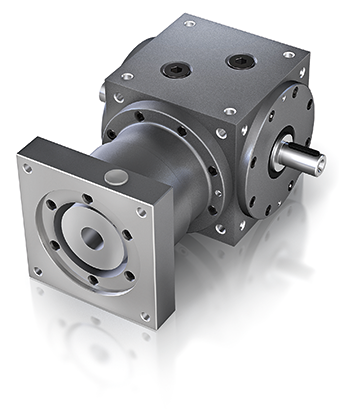

High speed leads to increased heat generation. Nidec Graessner shows that this is not a law of nature with its PlanetGear VRS High Speed gearbox series. This series is characterized by high traversing speeds and acceleration values as well as high deceleration without the gearbox overheating. Its use makes sense wherever automation and maximum speed go hand in hand.Speed ensures a competitive edge. When machine movements have to be particularly fast - especially with frequent stops and changes of direction - gearboxes deliver top performance. Especially in continuous operation, it must be ensured that the gearboxes are able to withstand the forces involved in the long term, so that a high thermal limit performance is guaranteed and that abrasion and susceptibility to maintenance are minimized. With a particularly compact design, a maximum acceleration torque of up to 3,700 Nm and a reduced torsional backlash of ≤ 3 arcmin, the VRS High Speed series is up to any automation project. At the same time, the gearboxes of this series run permanently quiet.

Your advantages

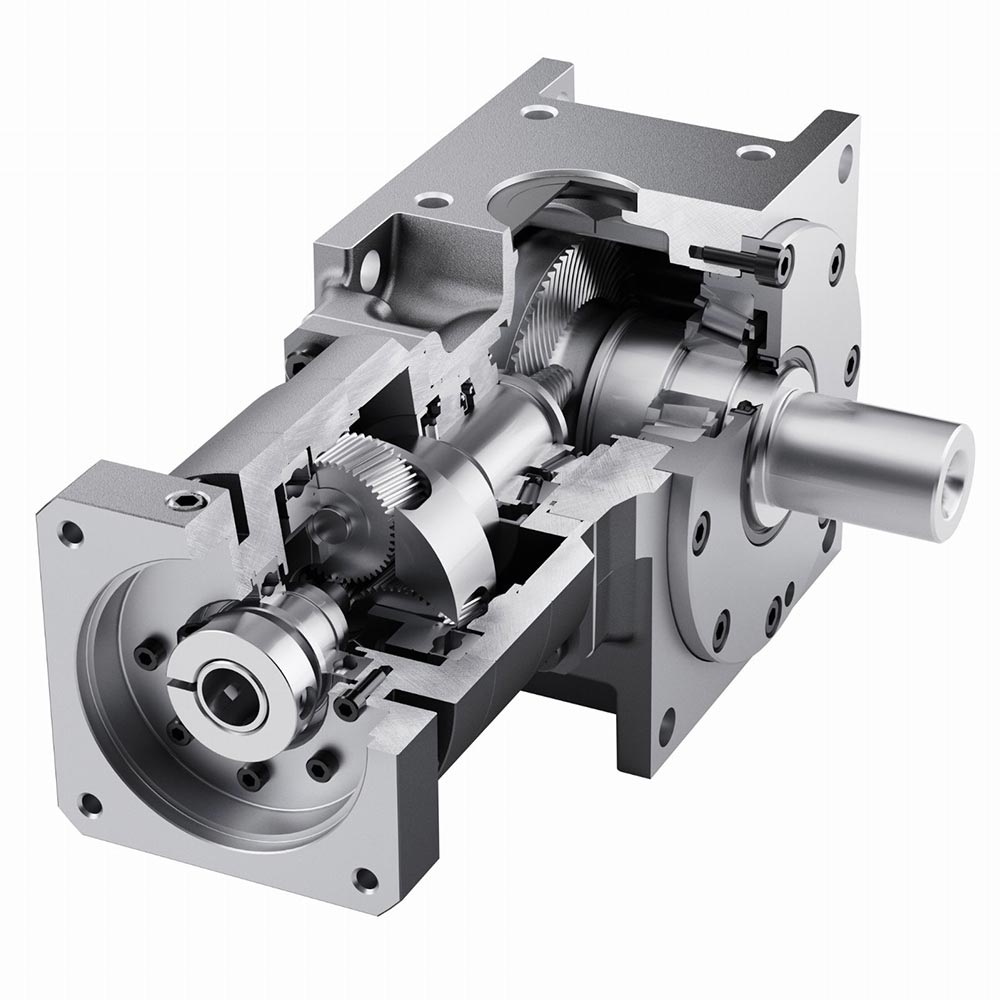

- Case-hardened helical gearing, tooth flank optimized for special accuracy and smooth running

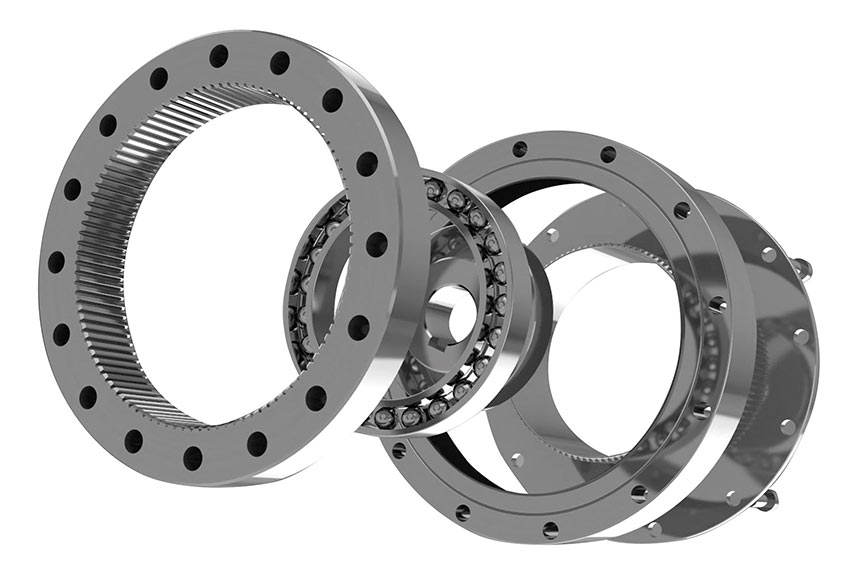

- One-piece output shaft and planetary gear carrier with two robust tapered roller bearings above the planetary gears; higher radial/axial load capacity, greater rigidity, torque density and improved safety factor with guaranteed tooth fit

- Cageless needle bearings provide excellent torque density and torsional stiffness

- Unique drive-side labyrinth sealing provides significantly reduced heating and higher system efficiency; IP65-rated version available

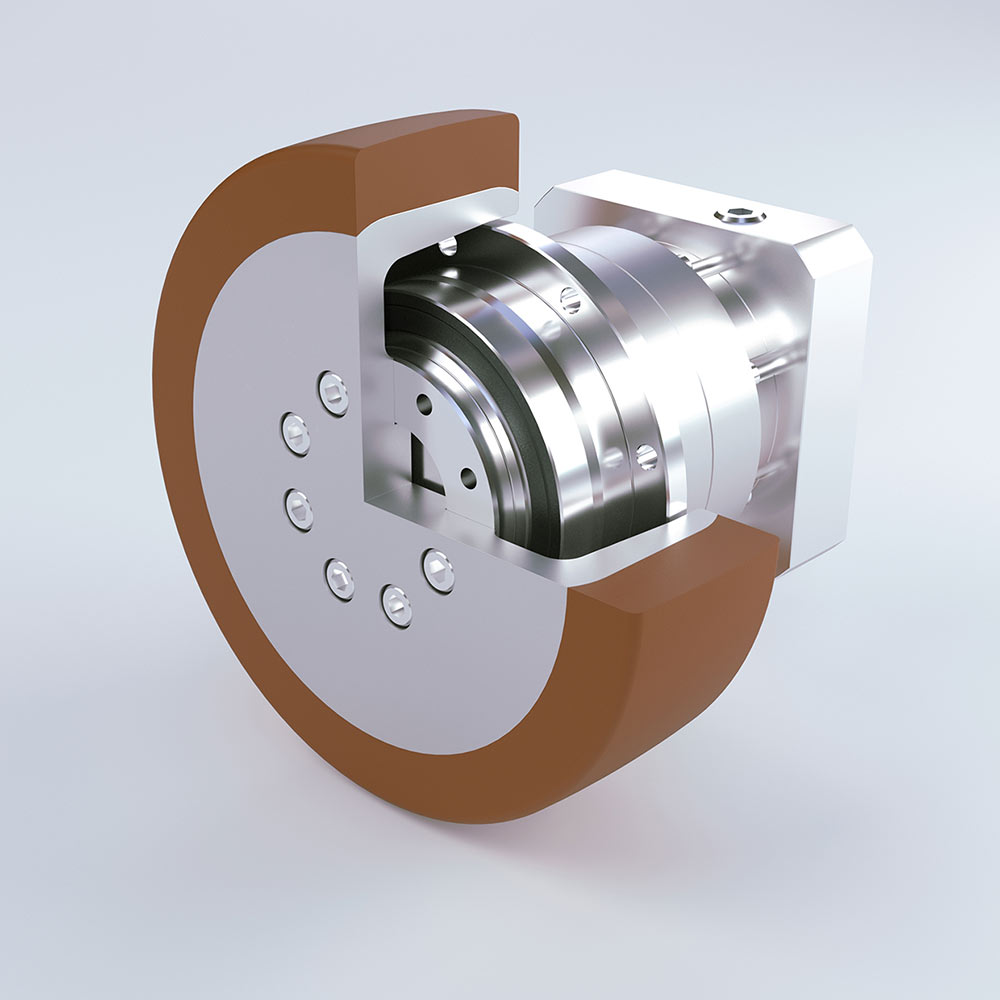

- Optimized mounting system with active centring on the motor centring diameter ensures correct fit of the motor. Motor can be mounted in any mounting position

- True concentric motor shaft clamping optimized for your particular motor; reduced inertia for dynamic performance and balancing for high-speed operation

- Ring gear machined directly into the housing, not welded or pressed in, provides better concentricity and eliminates speed fluctuations

More information about PlanetGear VRS...